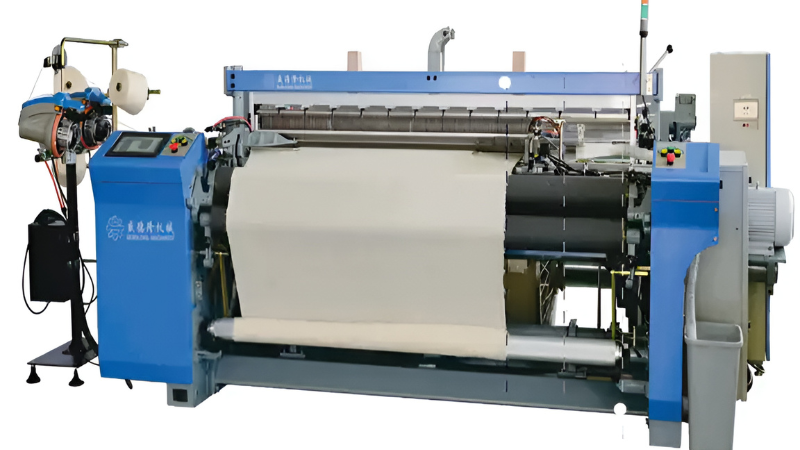

1. **Airjet Loom Lawn Fabric:**

Airjet looms are modern weaving machines that use compressed air to insert the weft (crosswise) yarn into the warp (lengthwise) yarn to create a fabric. In the context of lawn fabric, airjet looms can produce lawn fabric efficiently and at high speeds. The airjet technology allows for quick weft insertion, resulting in increased production rates.

2. **Shuttleless Loom Lawn Fabric:**

Shuttleless looms are a broader category of looms that includes various types of looms, such as airjet, rapier, and projectile looms. These looms are designed to eliminate the use of a traditional shuttle (hence "shuttleless"), which was used in older weaving methods. Rapier and projectile looms are other shuttleless options used to create lawn fabric and other textiles.

When it comes to the fabric itself, whether it's produced on an airjet loom or another type of shuttleless loom, the end product – the lawn fabric – is generally similar. The differences lie in the weaving technology and the efficiency of production. Shuttleless looms, including airjet looms, tend to offer advantages in terms of speed and automation compared to traditional shuttle looms. They can produce fabrics faster and with less manual intervention, resulting in potentially lower production costs.

In summary, both airjet loom and shuttleless loom technologies can be used to produce lawn fabric. The choice between them often depends on factors such as production speed, cost efficiency, and the specific capabilities of the weaving technology. The end result – the lawn fabric – will share similar characteristics regardless of the weaving method used, but the production process and efficiency may vary.

Whether airjet loom-produced lawn fabric is considered superior depends on specific factors and the perspective of the manufacturer, designer, and consumer. Here are some potential reasons why airjet loom lawn fabric might be considered superior in certain contexts:

1. **Production Speed:** Airjet looms are known for their high weaving speeds. They can produce fabrics more quickly compared to traditional shuttle looms, which can be advantageous for meeting high-demand production requirements.

2. **Efficiency:** Airjet looms are automated and require less manual intervention compared to shuttle looms. This can lead to higher efficiency in terms of both labor and time, resulting in potentially lower production costs.

3. **Consistency:** The automated nature of airjet looms can lead to more consistent fabric quality. The even insertion of weft yarns can result in a uniform appearance and texture in the fabric.

4. **Design Flexibility:** Airjet looms can handle complex patterns and designs with ease. They offer greater design flexibility, allowing manufacturers to create intricate patterns on lawn fabric.

5. **Reduced Waste:** Airjet looms tend to produce less waste during the weaving process due to their precision in yarn insertion. This can contribute to cost savings and a more sustainable production process.

6. **Lower Energy Consumption:** In some cases, airjet looms can be more energy-efficient compared to certain shuttleless or traditional loom types.

7. **Shorter Lead Times:** The faster production speeds of airjet looms can result in shorter lead times for delivering finished products to customers.

It's important to note that while airjet loom-produced lawn fabric might have these advantages, there are also considerations that may affect the decision to use this technology:

1. **Initial Investment:** Airjet looms can be more expensive to purchase and install compared to some other weaving technologies.

2. **Maintenance:** The complexity of airjet looms can lead to higher maintenance and repair costs compared to simpler loom types.

3. **Fabric Characteristics:** While airjet loom-produced fabrics can have many benefits, some traditionalists might argue that certain fabric qualities, such as hand-feel and texture, can differ from those produced using older methods.

4. **Specific Requirements:** Depending on the specific end use of the lawn fabric, certain weaving technologies might be more suitable. For example, if a particular type of finish or texture is desired, a different loom type might be preferred.

Ultimately, the choice between airjet loom-produced lawn fabric and other types of fabric comes down to a combination of factors including production goals, budget, desired fabric characteristics, and market demand. Each weaving technology has its own strengths and considerations, and the "superiority" of one over the other can vary based on individual needs and preferences.